Neodymium, iron, boron

Sintered

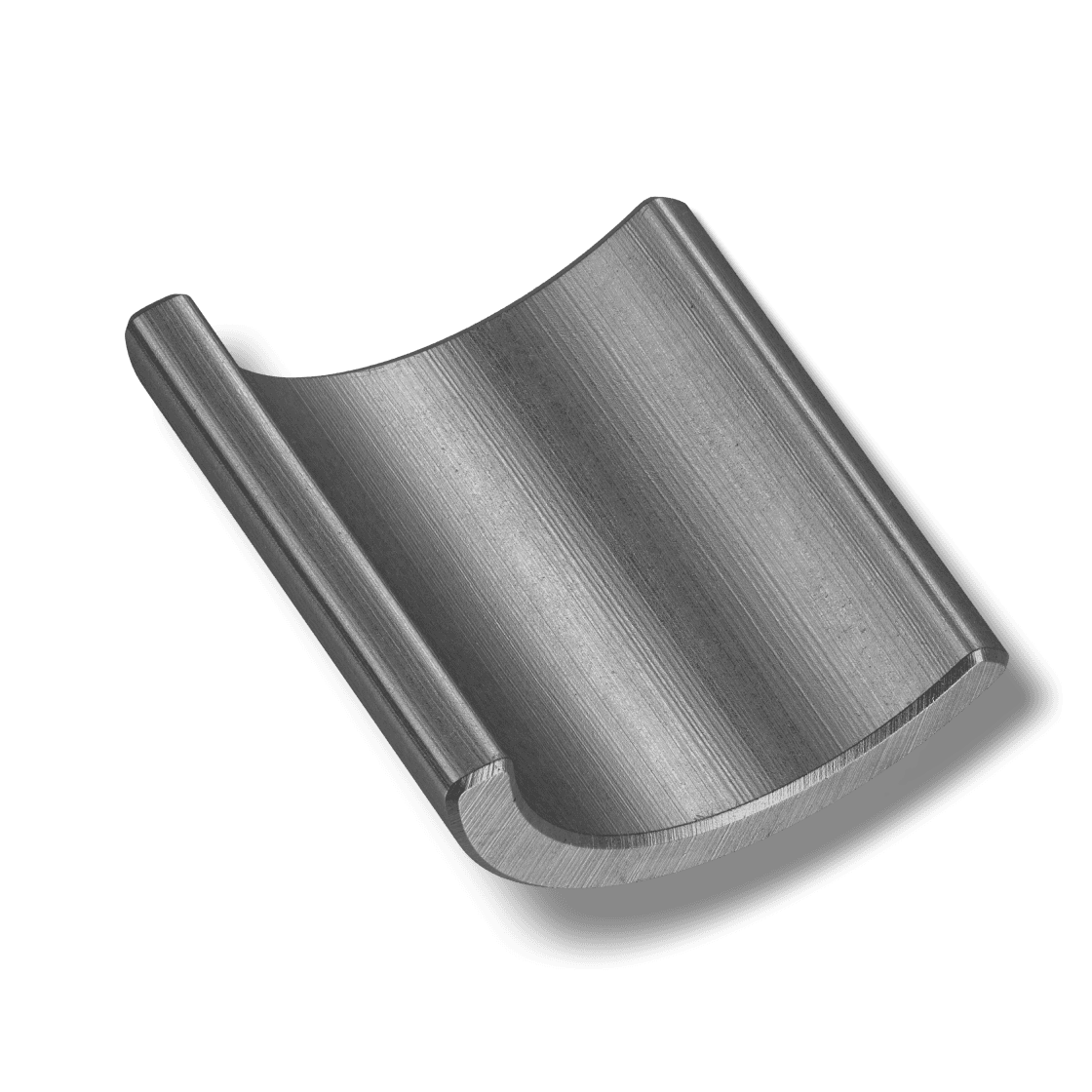

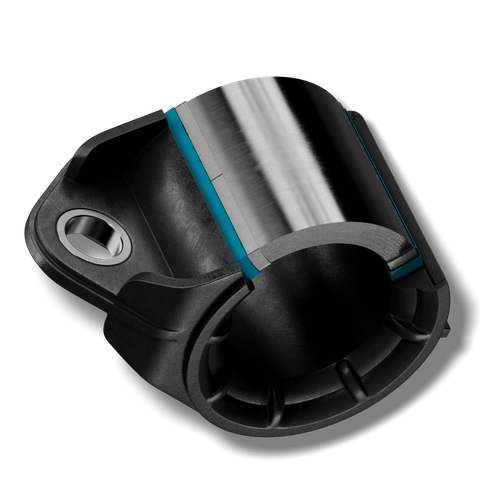

Versatile range of shapes

Product

Record-level performance

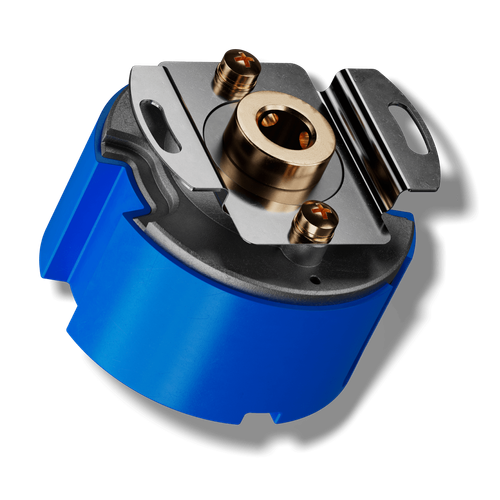

Sintered NdFeB magnets are considered to be the strongest magnetic material currently available. They are also highly resistant to corrosion. Although the neodymium-iron-boron mixture contains rare earths, their use can be reduced through certain processes. A further advantage is achieving the highest possible performance with the smallest size and least weight.

Compact size, low weight

Highest magnetic performance

High corrosion resistance and magnetic stability

General

Sustainable and highly flexible

The sintering of NdFeB magnets offers a number of advantages compared to other production methods. During sintering, a fine grain structure is created, which results in improved magnetic alignment and higher magnetic properties. It also allows use under high temperatures without any loss of magnetic or mechanical performance. Sintered NdFeB magnets enable a wide range of applications: a strong magnet with exceptional properties. The rare earths of the NdFeB magnet can be recycled.

Chemical Resistance

Largely Resistant

Alcohols

Gasoline

Motor oil

Organic solvents

Conditionally Resistant

Uric acid < 10%

Not Resistant

Salts in aqueous solution

Acids and alkalis

Citric acid

PRODUCTION PROCESS

Sintered magnets

The combination of material mix, the latest stripcast technology, grain size, oxygen content control and grain boundary diffusion make the NdFeB magnet an outstanding magnet that outshines the others.

NOTE

For years, Bomatec AG has been developing high-performance HRE-free NdFeB magnets and introducing new classes to the market in increasingly shorter innovation cycles. Our customers benefit from cutting-edge technology, high supply reliability, and sustainable material solutions.

As a technologically leading provider of permanent magnets, Bomatec AG offers a wide range of high-performance magnet materials, including modern HRE-free grades (heavy rare earth-free). Thanks to our years of experience and continuous development efforts, we have developed outstanding expertise in the production and application of NdFeB magnets without heavy rare earths.

Our engineering team is happy to evaluate your application for the use of alternative materials such as ferrites, pressed, or injection-molded magnets. With solid expertise, we analyze which materials can optimize the performance, cost, and sustainability of your application.

TECHNICAL DATA

A magnet with incredible performance.

What sintered NdFeB magnets can do.

NdFeB sintered

NdFeB sintered, corrosion stable

NdFeB sintered, corrosion & temperature stable

Further Questions? Talk to an Expert!

Carsten Weidner

Key Account Manager

Performance that delivers

Together we craft success stories

Our commitment is to bespoke product development that meets the highest quality standards and is tailored to the needs of our clients and their applications. It is only through our shared commitment to success and a focus on total customer satisfaction that successful partnership are formed.