Engineering at Eye Level

BOMATEC Expertise for the Automotive Sektor

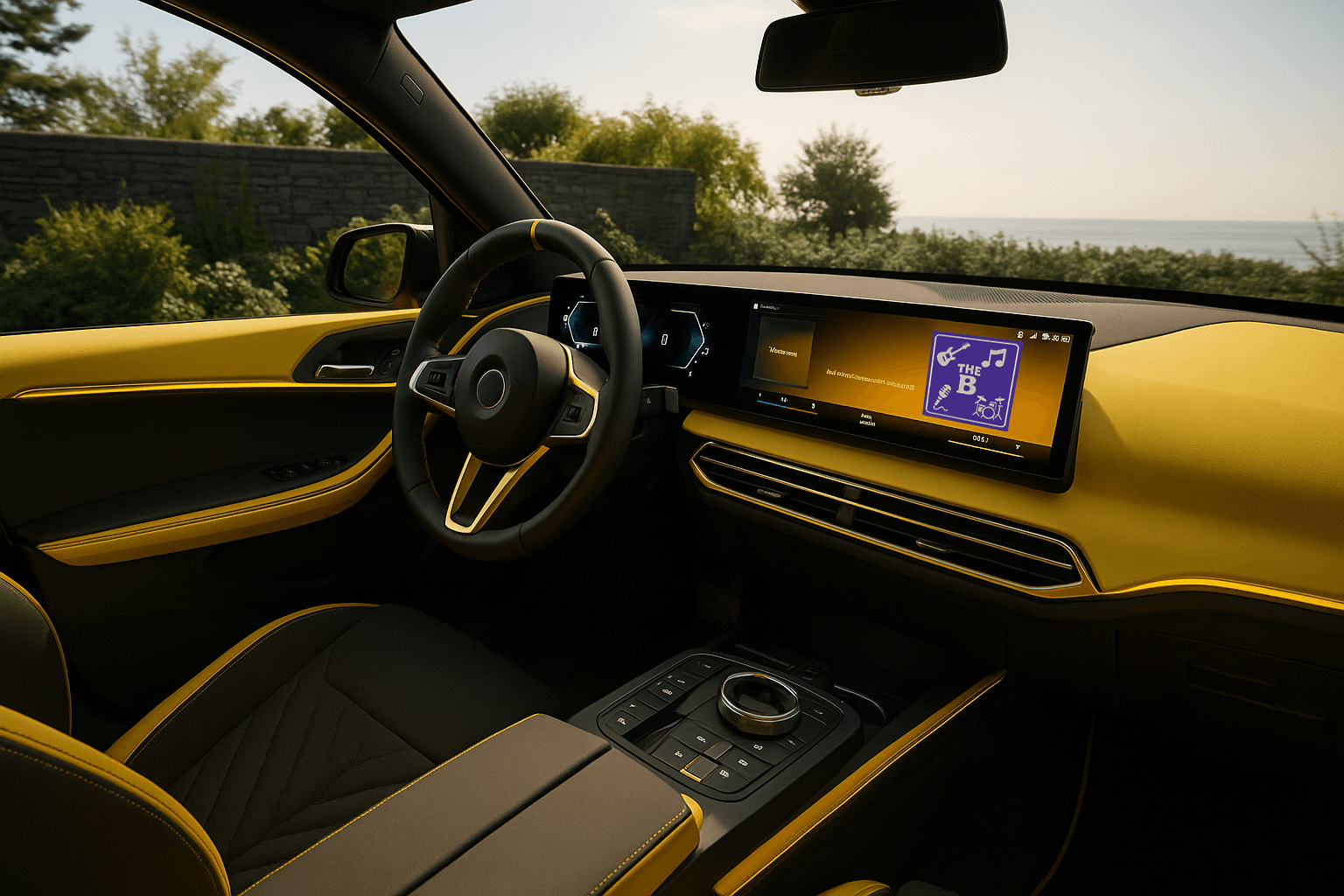

The automotive industry is undergoing transformation: electromobility, automated driving, and increasing demands for efficiency and safety are fundamentally reshaping technologies. BOMATEC meets these challenges with dedication and technical excellence. Automotive applications demand the highest levels of performance, precision, and reliability – qualities that our magnets consistently deliver. Whether in drive systems, vehicle sensors, electric actuators, or compact assemblies – we deliver solutions precisely tailored to each specific application. As an owner-managed company with many years of industry experience, we work closely with manufacturers and suppliers to develop precisely engineered magnetic components – from selecting the right materials and defining the geometry to final surface refinement and quality validation.

Certifications: ISO 9001 | ISO 14001 | IATF 16949

Diversified, fully integrated supply chain: certified, controlled, and produced.

Beyond China: Quality management: QPL | QA | QST

SUPPORT IN DEVELOPMENT

Engineering at eye level

BOMATEC and our entire supply chain are certified according to the most important international standards, including ISO 9001, ISO 14001, and IATF 16949. In addition, we actively address key topics such as TISAX, CO₂ footprint, environmental impact, material compliance (CMRT, EMRT, etc.), social responsibility, risk management, and more.

With locations in Switzerland, Canada, China, and our production site in Malaysia, BOMATEC manages the entire supply chain for you, integrating global suppliers from countries such as Japan, Taiwan, Vietnam, Malaysia, and beyond. This enables us to offer you an increasing number of strong alternatives to sourcing from China.

In many components, magnets perform critical functions that are essential to a vehicle’s operation – and a lack of expertise can have serious consequences. Through precise project and process management – using tools such as APQP, FMEA, SPC, MSA, and PPAP – we ensure that your quality, environmental, risk, and safety objectives are fully achieved. These goals are integrated into our processes as part of our Quality Planning (QPL), Quality Assurance (QA), and Quality Control (QST) systems.

Philippe Scheuber

Head of Sales

PERFORMANCE THAT DELIVERS

Together we craft success stories

We are dedicated to bespoke product development that meets the highest quality standards and is tailored to the needs of our customers and their applications. It is our collective commitment to success and a focus on complete customer satisfaction that fosters successful partnerships.