Samarium cobalt (SmCo2 and Sm2Co17), binding agent such as polyamide 12 or PPS

Plastic-bonded, injected

See data sheets

Product

Customized geometries and complex components

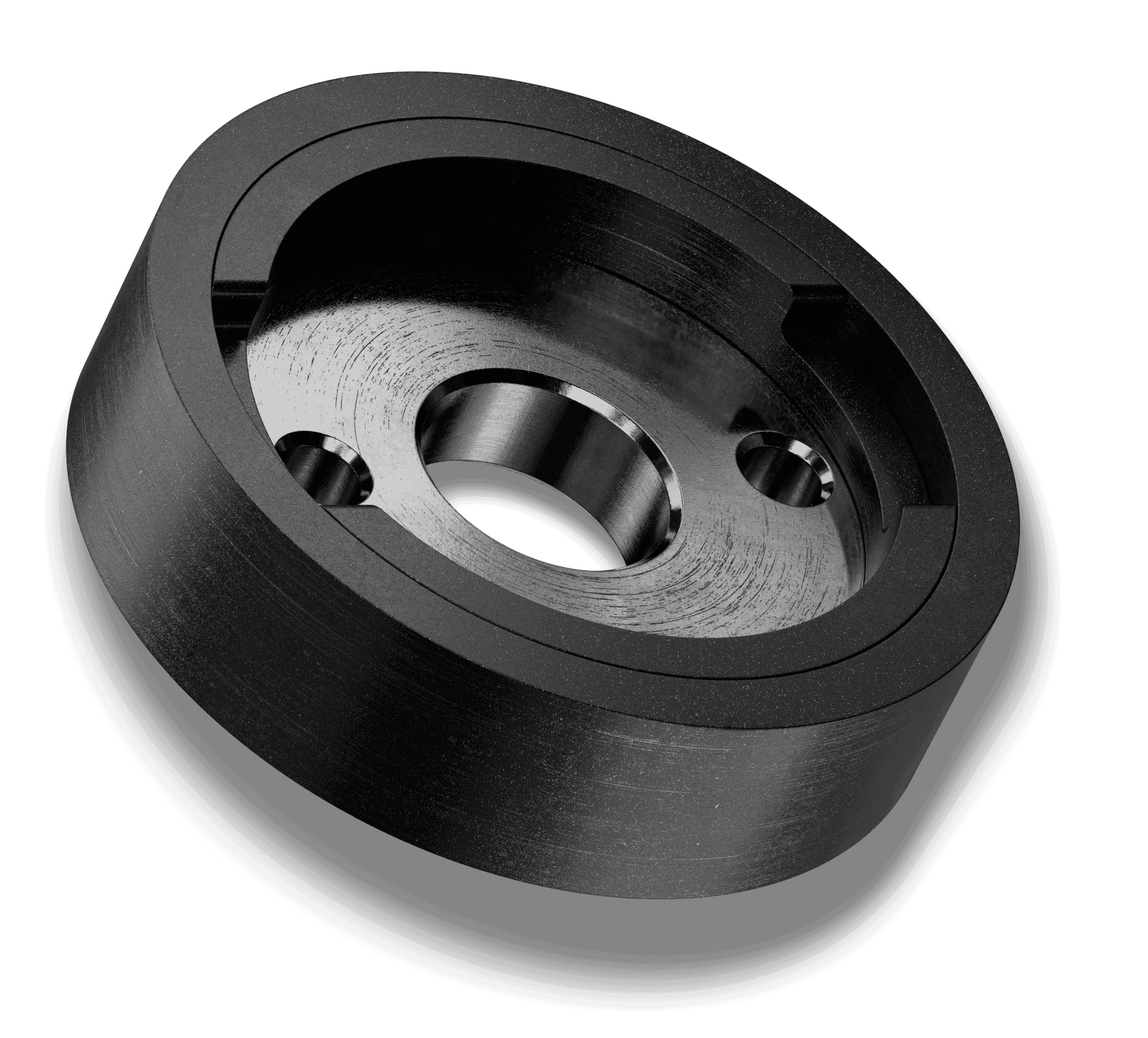

Injected, plastic-bonded SmCo magnets can take almost any shape, exhibiting a certain degree of flexibility. Thanks to the production method – injection molding – very high shape tolerances can be achieved. This can eliminate the need for additional processing steps. Moreover, it is possible to combine the magnets with insert parts in the same process step and create complex components – simplifying subsequent assembly.

High corrosion resistance

Almost any geometry

No further processing necessary

General

Many shapes and levels of magnetization possible

Plastic-bonded NdFeB magnets offer a significantly higher magnetic performance compared to hard ferrites. This allows for much smaller and complex system configurations. Along with their complex shaping possibilites, they are mechanically durable, and their magnetization can be freely selected. SmCo magnets are corrosion-resistant and have very low aging at high temperatures.

Chemical Resistance

Largely Resistant

Motor oil

Organic solvents

Salts in aqueous solution

Sea water

Conditionally Resistant

Uric acid < 10%

Not Resistant

Uric acid

Salts in aqueous solution

Acids and alkalis

PRODUCTION PROCESS

Injection molding process opens up possibilities

The SmCo plastic mixture is heated and injected into an injection molding tool. After the mold is removed you have the finished magnet, no further processing is necessary. Through the injection molding process all the benefits of pure plastic injection molding are combined with the fourth dimension – magnetism.

Note

The resistance to acids and alkalis depends on the plastic used. This needs to be checked for each specific application. Rare-earth magnets must be magnetized after the injection molding process using suitable magnetizing coils.

TECHNICAL DATA

What the plastic-bonded, injected SmCo magnet can do

The high-performance rare-earth magnets are elastic, exhibit high shape tolerances and can be prepared with insert parts for assemblies. They show minimal aging at high temperatures and maintain their shape stability.

SmCo injection molded, anisotropic

Further Questions? Talk to an Expert!