Iron oxide, barium oxide or strontium oxide, binding agents such as polyamide 6, 11, 12 or PPS, plastic-bonded

Plastic-bonded

Can take almost any shape

Product

Can take almost any shape

Injected, plastic-bonded ferrite magnets can take almost any shape, exhibiting a certain degree of flexibility. However, this is not comparable with purely injected plastics without ferrite content. Thanks to the production method – injection molding – very high shape tolerances can be achieved. This can eliminate the need for additional processing steps. Moreover, it is possible to combine the magnets with insert parts in the same process step and create complex components – simplifying subsequent assembly.

Application Fields

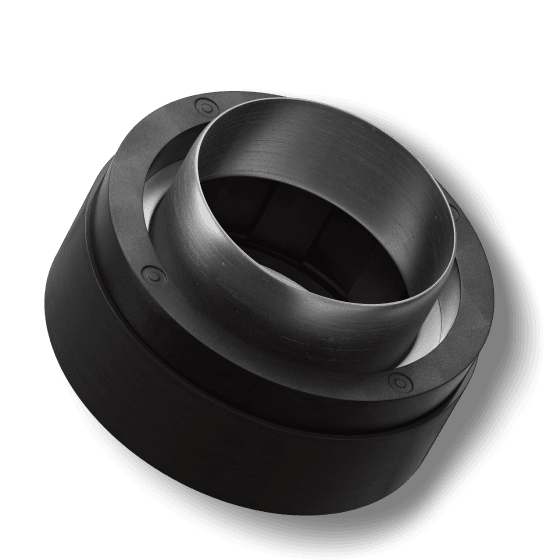

Coupling

Huge variety of shapes

No further processing necessary

Insert parts can be overmolded directly

General

Cost-effective base material

Hard ferrite powder is chemically very resistant to alkalis and acids. There are restrictions due to the plastic material used. In contrast to sintered magnets, much more delicate geometries can be produced with plastic-bonded magnets. Usually no further mechanical processing is necessary.

Chemical Resistance

Largely Resistant

Motor oil

Organic solvents

Salts in aqueous solution

Conditionally Resistant

Uric acid > 10%

Not Resistant

Uric acid

Acids and alkalis

Production process

Two advantages combined

Plastic-bonded ferrite magnets consist of iron oxides and a binding agent. These injection-moulded hard ferrite magnets can be magnetized and assembled directly in the tool. Insert parts can be overmolded directly. Combinations with additional overmolding with plastics as connecting elements are also standard. The injection molding process combine all the benefits of pure plastic injection molding with the fourth dimension – magnetism.

Note

The plastic-bonded ferrite magnet is magnetized and assembled in the tool. The complete part can be produced in one operation.

TECHNICAL DATA

What the plastic-bonded hard ferrite magnet can do

Plastic-bonded hard ferrite magnets are relatively resistant to chemicals and can be preferentially aligned or magnetized directly in the injection molding tool.

Ferrite injection molded, anisotropic

Further Questions? Talk to an Expert!